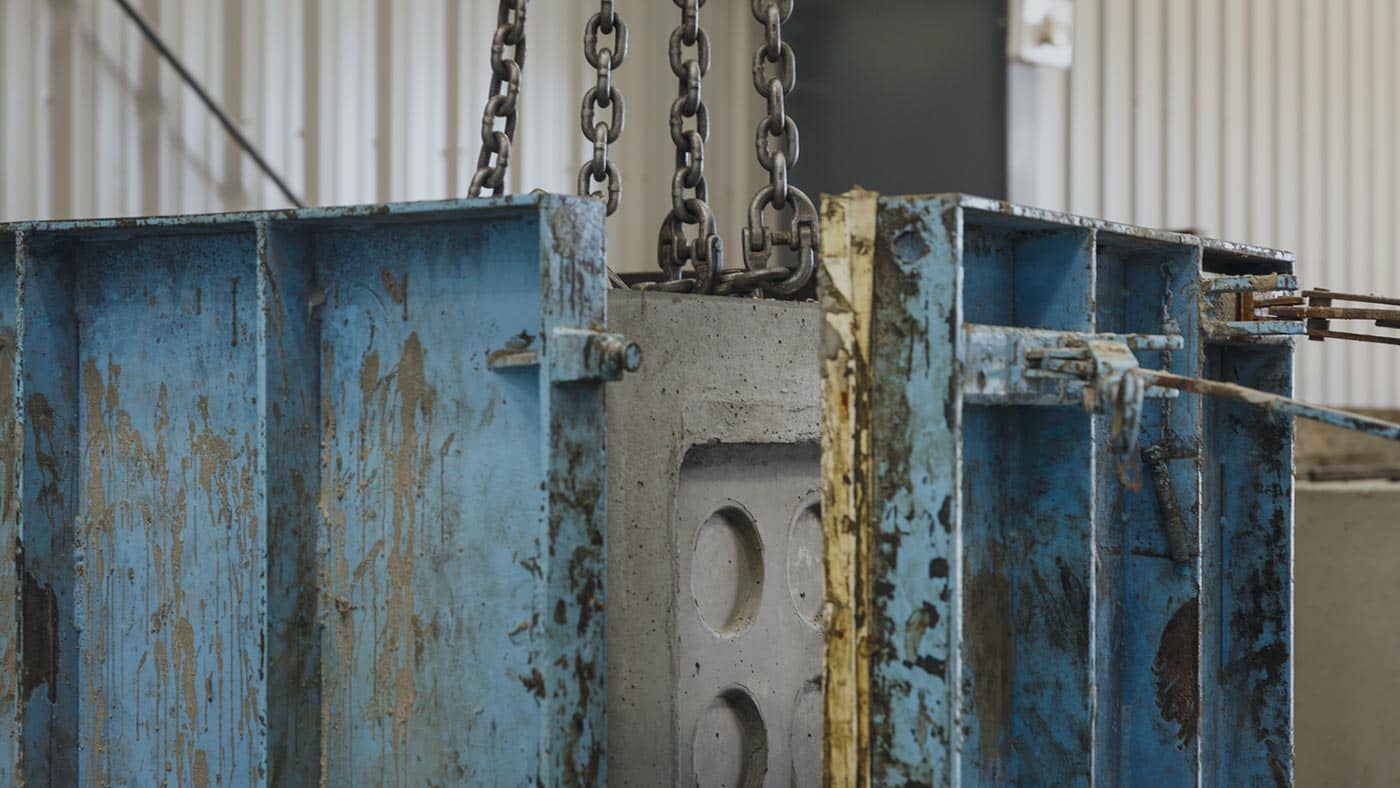

At Locke, we take pride in the relationships we create through the products we build. Though we do have some products readily available “on the shelf”, we primarily create custom pieces for our clients by solving their technical problems in order to create a design that meets their needs.

We consider this service as part of our larger process, even referring to ourselves as “Your personal precast division.” With our refined design process and our years of experience in custom solutions, we try to help customers see the benefits—and flexibility—of precasting. We understand that good customer service is a cornerstone to product creation and we take our process very seriously and our products are a direct result of that.

OUR APPROACH TO CUSTOM

Just because a product is “custom” doesn’t mean the approach has to feel that way. Since our inception, we have developed unique approaches to precast design that get results without all of the typical design headaches like decision fatigue, delayed build times, or blatant delivery issues. Our tried-and-true process allows us to stay on task while still remaining flexible in pursuit of what we find incredibly important: solutions. Have questions about our approach to precast? Reach out, we’d love to talk about it.

IMPROVING PROCESSES

We actively refine our process for better efficiency, shortened production times, and smarter communication throughout the product lifecycle. As we move forward as an organization, we are considering even better ways to implement technology into our daily workflows, creating tighter feedback loops and simplify progress updates. We’re even actively investing in our proprietary software that tracks hours and production timelines, leading to better, more transparent billing and scheduling.

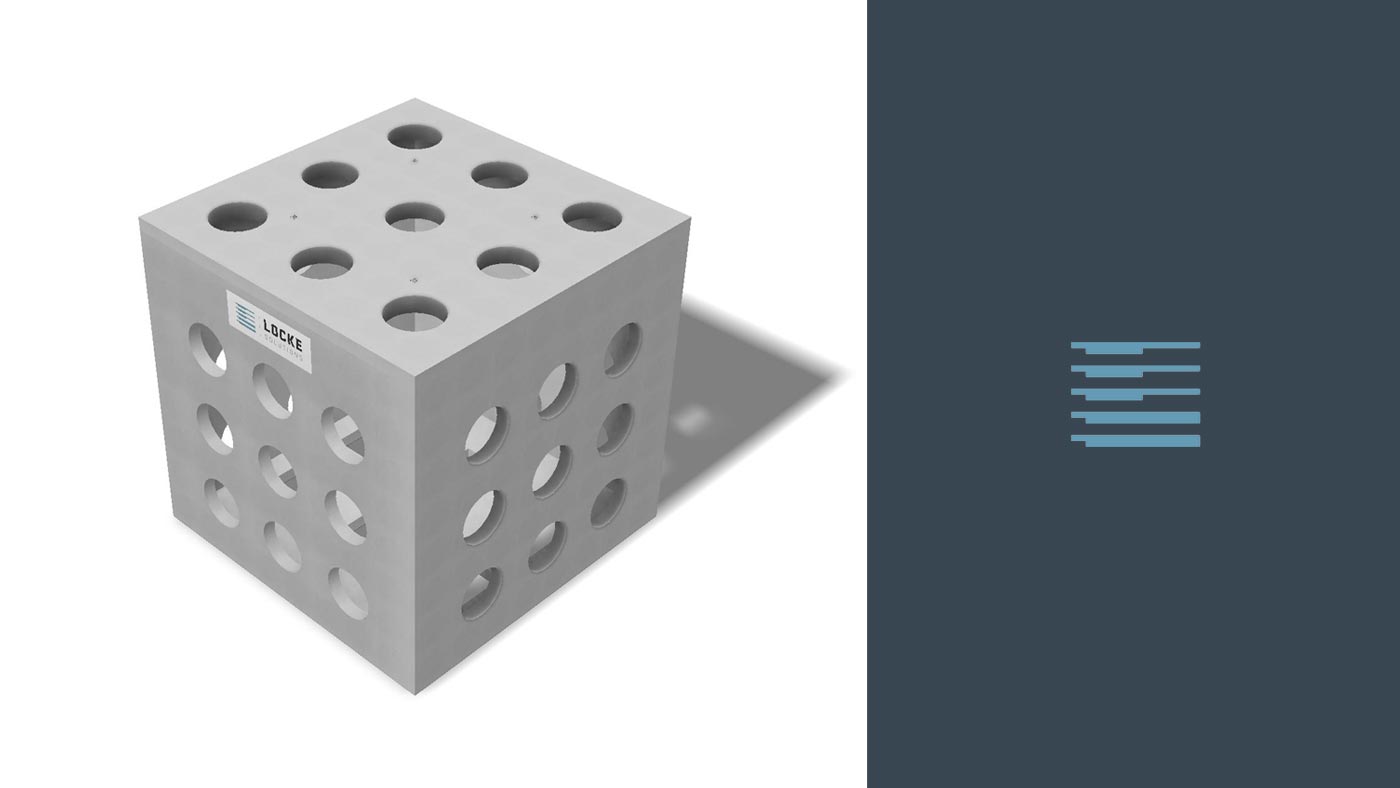

GROWING OUR CAPABILITIES

A process is only as good as your ability to implement and support change That’s why Locke continuously improves our industry-leading plant, ensuring what we can dream up can swiftly become reality. From our recent investment of 2 new crane 45′ Proserve bridge cranes to our proprietary production application, Locke puts it money where its heart is: better service.

And as 2020 comes to a close, we’re thankful for all the little improvements on our horizon and look forward to sharing them as they are deployed. We truly are a solutions company, even for ourselves.