Leading Precast

Contact Sales

Every parking lot and city walkway are littered with light poles illuminating and creating a more inviting, safer space. Most people take it for granted and only notice the light poles when they’re absent creating a dark and precarious feeling at night. But if asked, the contractors installing those light poles will probably tell you how much of a pain it is to build this relatively unnoticed feature. And it’s not the actual light pole that is difficult to install, it’s the concrete base that anchors this light pole that creates so much coordination and effort.

Some parts of the country have discovered the relatively unknown secret of prefabricated concrete light pole bases, also known as precast concrete bases.

The traditional process of constructing concrete light pole bases in the field consists of drilling an excavation, placing formwork or cardboard tubing to create a round shape extending a few feet above grade, fabricating and placing a rebar cage, fabricating and securing conduit or openings for electrical wiring, and setting a template to maintain the exact spacing and vertical alignment of specific anchor bolts. At this point, a third-party inspection is typically required to ensure the proper reinforcing steel is used and placed in the correct position, the excavation and formwork have been correctly established, and finally, the anchor bolt and conduit positions are properly placed and secured to prevent any movement during the concrete pour.

Once the light pole base setup has been confirmed, ready-mix concrete is scheduled for delivery. Getting the 80,000 lbs ready mix truck close enough to the light pole base can be challenging, but once ready, the concrete placement beings and a geo-tech inspector is typically required to be onsite to take concrete samples during the pour. After the concrete has been placed and the concrete has cured, typically 7-10 days, the formwork or cardboard tubing needs to be removed and the light pole base needs to be patched and cleaned up to meet aesthetic expectations. All in, this process can take anywhere from 7 to 14 days, and that is assuming no downtime due to rain events or scheduling conflicts with the inspector, geo-tech technician, concrete and electrical trades, or ready-mix concrete delivery. It is a lot of work and coordination for a simple light pole base.

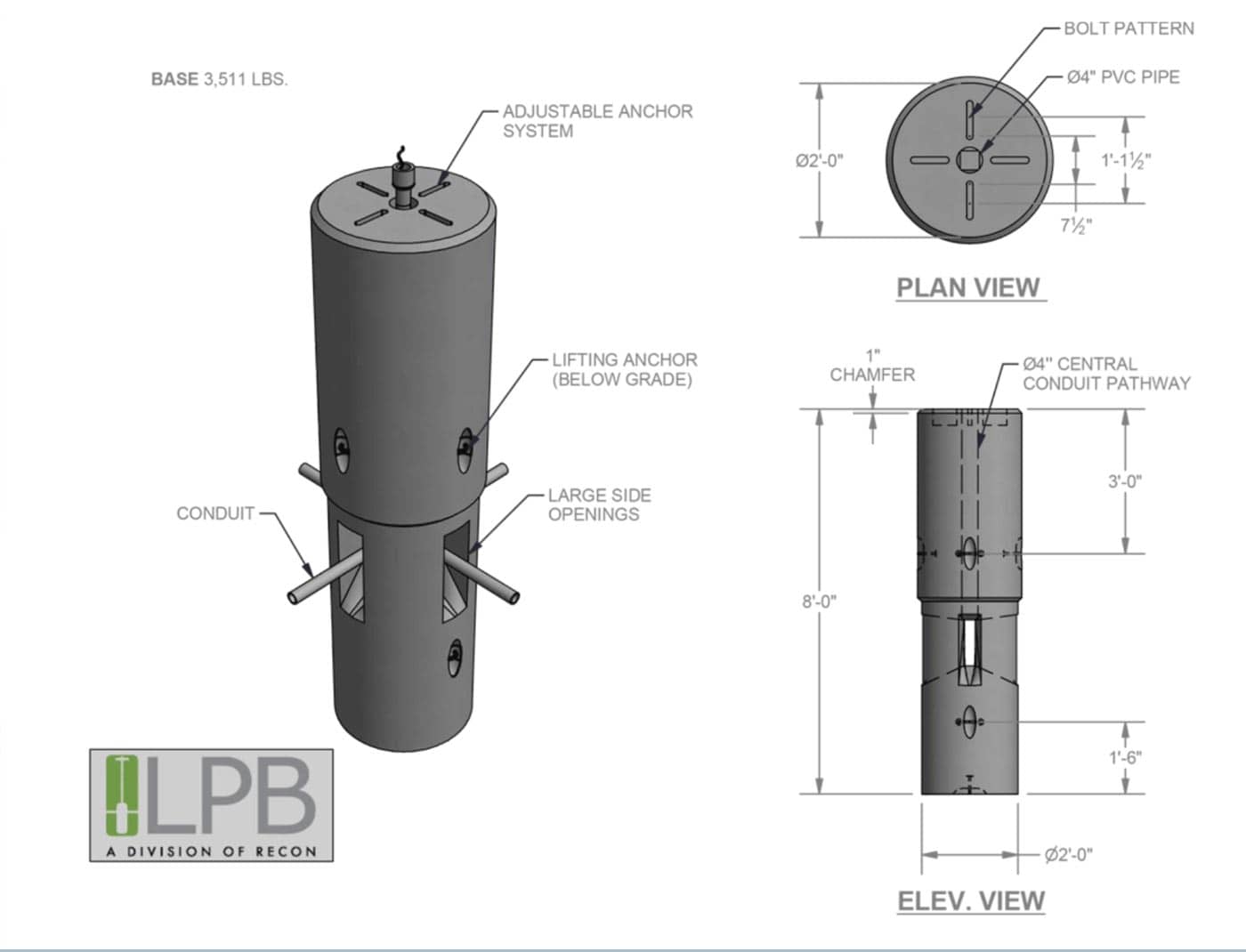

LPB set out to make this process easier. These precast concrete light pole bases can be made in advance and stocked to be ready when the customer needs them. The patented bolt pattern system allows for varying bolt patterns to determined onsite to fit exactly with the pole being attached.

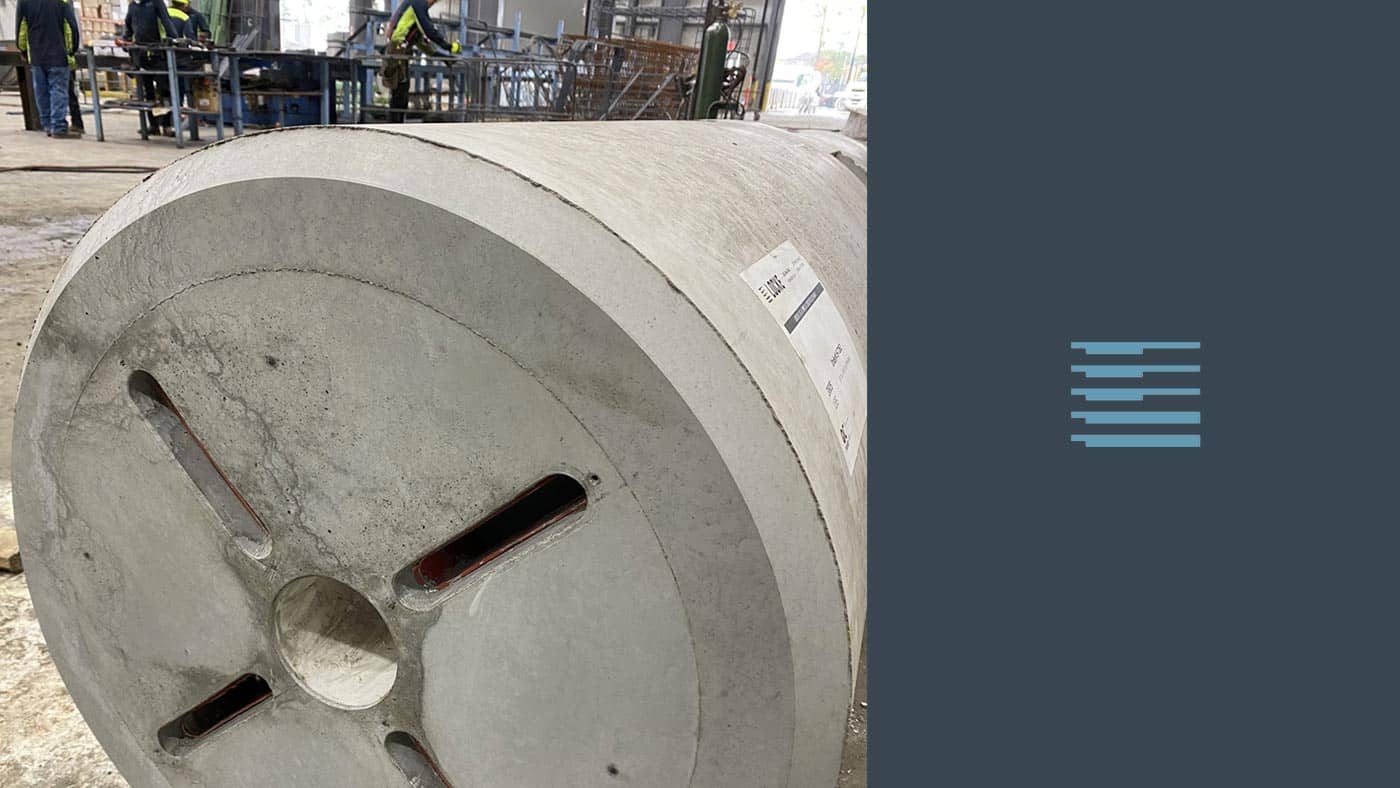

This simple system changes the whole schedule and process for installing light pole bases. Not only does it simplify the 7-14 day process down to one day, but it also leaves the owner with a better quality pole foundation. The LPB’s are built in a controlled factory environment with high-strength concrete and constant quality control monitoring throughout the manufacturing process.

The contractor can control the schedule of installation and finish in a fraction of the time while virtually eliminating the risk of weather or inspection delays…all at a lower installation cost and headache factor. The LPB is delivered cured to strength, consistent, and clean with no need for additional aesthetic touchups.

Locke Solutions has recently partnered with the LPB as a licensee for the patented concrete light pole base system.

It is not a surprise as there is a natural fit between Locke and LPB as both companies have a culture and purpose revolving around making life easier for our customers. LPB has taken the cumbersome process of constructing concrete light pole bases and turned it into a simple and quick step in the project.