Leading Precast

Contact Sales

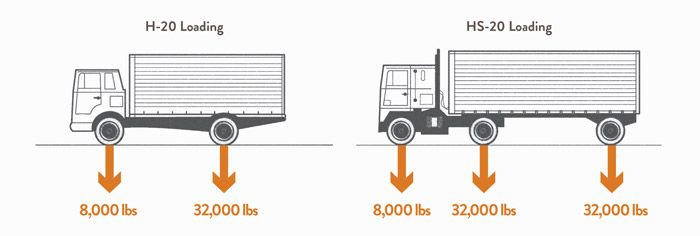

This image shows the potential heavy-duty traffic loading imposed on underground trench structures.

This image shows the potential heavy-duty traffic loading imposed on underground trench structures.

What does HS-20 traffic rating mean?

This is the term used by AASHTO and ACI to describe normal MOVING traffic loading conditions up to 18-wheeler loading. This loading assumes a 16,000 lbs wheel load and therefore a 32,000 lbs axle load. It also takes into consideration the additional loading that occurs from moving vehicles. These loads are called IMPACT and LIVE LOAD SURCHARGE and are an additional safety factors that help prevent underground enclosures from having a structural failure and collapsing in from traffic conditions. There are few construction materials that are designed to withstand these type of loadings other than concrete and cast iron (or ductile iron) steel.

What is the difference between H-20 and HS-20?

Generally speaking, these terms are used interchangeably, but there is a slight difference. You can see the different diagrams showing the difference between H-20 and HS-20. There is minimal, if any, cost savings from designing structures with H-20 versus HS-20, so my recommendation is to always require HS-20 loading if you think there is any possibility of vehicle traffic.

What does the number “44” represent in HS-20-44?

Quite often, this number “44” is mistakenly assumed to mean 44,000 lbs in some design context. The number “44” actually refers to the year, 1944, in which the HS-20 traffic loading conditions were originally developed by AASHTO.

What is the difference between HS-20 and Tier 22 Ratings?

It is difficult to compare these two designations but there are some key points that people sometimes confuse when dealing with different load ratings. One of the differences between these ratings, is HS-20 refers to traffic loading conditions with wheel loads up to 45,136 lbs, when considering impact and load factors, while Tier 22 is using a 33,750 lbs wheel load tested in a vertical position. The ANSI/SCTE 77 2007 code for the various Tier designations include Tier 5, 8 ,15, and 22 are meant for small boxes with only INCIDENTAL traffic conditions. Any underground enclosures with potential wheel loading conditions should consider using HS-20 traffic loading criteria and materials should be limited to concrete, steel, and/or cast/ductile iron materials.

Many marine facilities have heavy-duty loading conditions due to storage containers and the equipment needed to handle these containers.

Many marine facilities have heavy-duty loading conditions due to storage containers and the equipment needed to handle these containers.

When do I need to consider designing above & beyond HS-20 traffic rating?

It is smart to consider special designs if you have larger than standard 18-wheeler traffic driving over your structures. Large construction equipment including front loaders, forklifts, mobile cranes all should be considered when installing underground structures. Airport, marine, and railroad facilities should also be looked at closely to determine what type of loading conditions will be present. From a cost/benefit analysis, it is very easy to justify the cost of a heavy duty load design versus the risks of a catastrophic failure because of an unexpected piece of equipment needing access on your structure.

What are the concerns when installing an underground enclosure?

The most critical factors include the type of loading conditions that could create a structural failure leading to the collapse of the enclosure. Vehicle loads on top of the enclosure dictate how the top and bottom of the enclosure should be designed. Lateral loads from soil, water, and loading derived from moving vehicles impact the design considerations of the side walls of an enclosure.

What is the difference between HS-20 and HL93?

HS-20 is the truck live loadings of the AASHTO specification, where H stands for highway, S stands for semi-trailer, 20 stands for 20-ton weight of the tractor (first two axles). Each axle will carry the loads as follow, the first axle carries 8,000 pounds, the second axle, 14 feet away carries 32,000 pounds and a single-axle semitrailer 14-30 ft away from the second axle carries 32,000 pounds.

HL93 is the Basic LRFD Design Live Load, where H stands for Highway, L stands for Loading and LRFD stands for Load and Resistance Factor Design. The HL93 design loading consists of a combination of “Design Truck Plus Design Lane Load” or “Design Tandem Plus Design Lane Load” which ever produces the worst case. A “Design Truck “is same as the HS-20 load. The “Design Tandem “consists of two axles, each axle weighing 25 kips spaced 4 ft apart. The Design Lane Load is equal to 640 pounds per linear foot. This uniformly distributed load is designed to apply on the above grade bridge deck but It does not apply to below ground structures per ASTM C1577.