Leading Precast

Contact Sales

This is such a common question but rarely seems to get answered.

Why? Mainly because there are a lot of factors that can affect the cost of a precast concrete structure. Do not worry, in this article, we will give guidance on how much to expect to pay for various types of precast concrete. The focus of this article will be on underground concrete structures including manholes, handholes, box culvert, sumps, foundations, utility trench, stormwater trench, along with how to estimate your delivery costs.

If you are asking this question about precast, you probably realize or have been told there are cost savings utilizing precast structures versus the conventional cast-in-place construction method. Although we will discuss some of the differences here, we do have a more in-depth article contrasting these two construction methods.

Let’s get right to it. Precast concrete structures generally range in cost from $375 to $1,300 per cubic yard. Yes, this is a wide range, so let’s break this down into more specific situations. Obviously, the simpler a structure is, the lower the cost per cubic yard. (And for those of you more inclined to think in terms of cubic feet, there are 27 cubic feet in a cubic yard)

COST OF A SIMPLE PRECAST BLOCK

A good example of what I like to call “dumb” concrete would be a concrete ecology block. This “eco-block” is a block of concrete generally 2 ft wide x 2 ft tall x 4 ft long and would typically cost $375 to $425 per cubic yard. They have a groove on the side, and they are stacked and interlocked to create wall systems generally used to separate material stockpiles. These wall systems are common at ready-mix operations separating the various rock and sand aggregate materials used in batching concrete.

We call this “dumb” concrete because it is such a simple concrete structure typically with only a single lifting anchor cast into it. Usually, there is no steel reinforcing, no additional embedded steel components, and no CAD or engineering design work required. The concrete mix design is typically very basic and low strength and generally precasters will have a very simple and inexpensive casting mold to produce these ecology blocks. All in, a precast structure like this will have one of the lowest costs per cubic yard price tag.

COST OF PRECAST PANEL (NON-ARCHITECTURAL)

Now, let’s take a step up in complexity. Precast concrete panels (or slabs) will typically range from $450 to $750 per cubic yard. This is a wider range of cost because there are a wider range of options and factors affecting the total cost. If you consider the differences between a 6” thick panel versus a 12” thick panel, you have much of the same labor costs associated with setting up a casting bed for both thicknesses. You may have more steel reinforcing and obviously, you will have two times the amount of concrete material, but the total labor costs are spread out over twice as much cubic yardage equating to a lower cost per cubic yard for the thicker panel. Other factors affecting the cost could be the amount of miscellaneous steel embed plates or connection components cast into the panel. Are these components plain steel, galvanized steel, or stainless steel? Are the components stock items readily available or are they custom-built for the project? Concrete panels also have various finishes and edge treatments depending on the final use of the product. If the panel requires beveled edges, specific textured finishes, or integral color, obviously these material and labor costs start adding up. As you move into true architectural finishes, the cost per cubic yard can dramatically increase above $750 per cubic yard depending on how specialized the finished product is expected to be.

COST OF STANDARD MANHOLES, JUNCTION BOXES, CATCH BASES & INLETS

Next, we will focus on the general costs for more traditional precast structures for storm water drainage purposes. Precast manholes, junction boxes, catch basins, and inlets typically range from $700 to $1,000 per cubic yard. Often these structures are standardized through city or state specifications eliminating the need for design analysis and customized CAD drawings. This standardization also lends itself to standardized casting molds and more repetitive production processes, which helps reduce labor costs per cubic yard. Except for typically lifting anchors, these drainage structures also have very few embedded components. In addition to this range of costs, most of these structures are accompanied by a cast iron or steel component such as a manhole access cover or drainage grating. A good rule of thumb is to assume $300 to $500 per structure for this cast-iron access component.

COST OF CUSTOM PRECAST DRAINAGE STRUCTURES

So, what is the impact when a project needs more job-specific concrete structures? Often the standard “city” catch basin is not sufficient for many different reasons:

- The size and angle of connecting pipes require a larger junction box base.

- The traffic loading conditions are heavier than standard HS-20 loading.

- The top elevation of the structure is critical and needs to be exact.

- The storm water could have contaminants requiring a more durable concrete mix or internal coating.

- The surrounding soil conditions may warrant sulfate-resistant concrete or an external protective coating.

Whatever the reason, when there is a need for a more specific structure, often times a more labor intense setup for the casting mold is needed along with additional engineering and CAD work. The upside in this situation is getting a precast structure to fit the exact need of your project versus modifying your project requirements just to accommodate a standard catch basin size. The downside is the custom precast structure will likely cost a little more and require a longer lead time. As you can see, there are several factors that can influence the cost of a custom concrete drainage structure, but the general range of cost is $750 to $1,100 per cubic yard of concrete…and again, don’t forget the additional $300 to $500 per structure for the steel access components.

COST OF STANDARD UTILITY VAULTS, ELECTRICAL MANHOLES, COMMUNICATIONS MANHOLES, AND HANDHOLES

Taking another step up in complexity, we will look at structures typically used in the “dry utility” market for power, electric, and communication distribution underground. The typical cost for utility vaults, electrical manholes, communication manholes, and handholes ranges from $700 to $1,100 per cubic yard. Although these structures can be very similar to standard precast drainage structures, they typically require more embedded items to accommodate the connection with buried conduit and to help facilitate the installation of electrical or communication wires. These embed items could include anchors for pulling cable, electrical grounding devices, conduit couplers are known as terminators, cast-in threaded inserts to accept bolts for equipment installation, and floor sumps to aid in pumping water out of the structure. Another large cost associate with these utility structures is the access cover or hatch. With the need to access these structures more often, the access hatches are typically galvanized steel or aluminum and require more safety features than a typical stormwater manhole. These access hatches can vary significantly with size, material, and load rating being the primary cost differentiators. The cost for these hatches could range between $300 to $1,500 per structure with a smaller 2 ft x 2 ft hatch on the lower end and a 4 ft x 8 ft on the higher end of the cost spectrum.

COST OF CUSTOM UTILITY STRUCTURES

As is the case with custom drainage structures, the cost can vary for underground concrete utility structures with more customized sizing and features. Some of the common factors to impact the cost include:

- The type of support and racking system used to support cables.

- The required pulling capacity and material of pulling irons.

- The configuration of the sump to facilitate pumping of the structure.

- Depth of the duct bank requiring a deeper structure and creating higher lateral earth and water pressures on the vault.

- Traffic loading conditions greater than normal HS-20 loadings such as heavy equipment, aircraft, heavy-duty forklifts, and rolling cranes.

- Requirements for non-ferrous reinforcement.

- Requirements for grounding devices integral to the precast vault.

- External coatings or the use of additives to seal off micropores in the concrete due to contaminants in the soil.

Certainly, these different factors can significantly impact the cost, but a general range of cost for these custom utility structures is $750 to $1,300 per cubic yard plus the addition of $300 to $1,500 per structure for the access hatch described in the previous section.

COST OF CONCRETE SPREAD FOOTINGS (FOUNDATIONS)

Precast concrete spread footings come in various shapes and sizes with a cost range of $800 to $1,000 per cubic yard of concrete. Normally, these footings will have a galvanized steel plate or anchor bolts embedded which will add another $50 to $300 in cost for each pedestal mount associated with the footing. The type of steel, the thickness of the plate, and the type and size of anchor studs all have an impact on the cost of embedded weld plates. Typically, these embedded weld plates will cost between $50 to $150 for each one. Cast in anchor bolts can vary greatly depending on the diameter, length, and grade of steel required. Typically, anchor bolts will cost between $20 and $65 each, and generally spread footings will have 4 to 6 of these anchor bolts for each support pedestal. Spread footings can come in an endless variety of configurations and sizes. The base slab of the footing can be manufactured in rectangular or circular dimensions at any thickness while the raised pedestal of the footing can also be produced in a round or rectangular shape at any height necessary. Sometimes the design requires to have multiple pedestals located on the same base footer slab, which can easily be accommodated in the precast setup. Another important note, if the project has several spread footings of the same dimension, there can be significant cost savings on the casting mold setup. It is a good idea to consult with your local precaster to determine the most economical options when determining your layout of spread footings on the project.

COST OF CONCRETE SUMPS

The cost of concrete sumps will typically range between $750 to $1,200 per cubic yard. Precast concrete sumps come in a range of sizes as small as 2 ft x 2 ft up to mega-size sumps with length and width dimensions of 30 feet and greater. Generally, these larger sumps can be difficult to precast because of challenges in shipping. When the smaller dimension of width or length is greater than 16 feet, the costs of shipping start increasing exponentially due to the required permits and escorts needed. If the volume of the sump is more critical than the shape, precast can normally be incorporated in the design by creating a rectangular design and limiting the inside width of the sump to 10 ft. The required volume of the sump can be attained by increasing the length and depth and you get the benefit of reduced shipping costs (shipping costs are discussed below in this article). Sumps will normally have multiple manway access openings along with vent pipes and inspection ports. Depending on the type of material (aluminum, steel, cast iron) and the size of the access, the cost will range between $300 to $1,500 for each access. The cost of vent pipes will range between $40 to $100 each depending on the size and material. Another potential cost associated with sumps can be the lining of the internal walls. In many cases, the water contained in sumps can have abrasive chemicals requiring a sprayed-on liner coating or a liner material integrally cast into the concrete wall. These liner systems can vary widely depending on the application needed, but internal liners can cost between $20 to $60 per square foot of surface area.

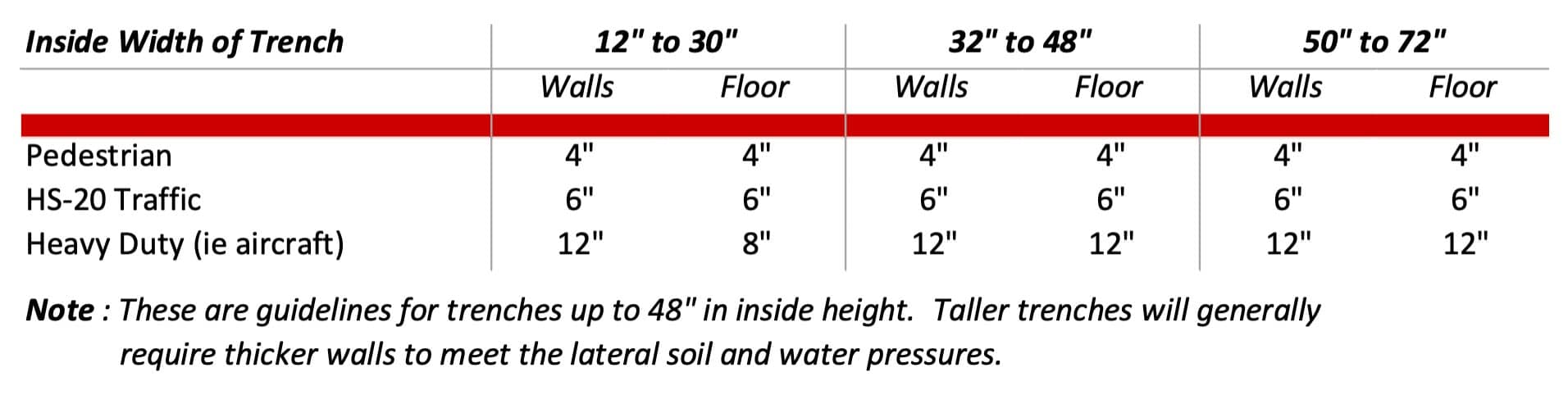

COST OF CUSTOM TRENCH

Concrete trenches are used for various applications including for the protection of utility lines such as water or air, chemical piping, electrical and communication lines, power transmission lines, or for the conveyance of storm water. We will separate these trench systems into two categories, utility trench, and drainage trench, and give you a cost breakdown for each. Trench systems are typically priced out per linear foot, so before we dive into the cost per cubic yard of concrete, let’s tackle the next question you might have. “How thick should we estimate the walls and floor of the concrete trench to be?”

This question has a wide range of answers, so we have created a chart below to give general guidance.

COST OF UTILITY TRENCH

The cost of concrete utility trenches will generally range between $800 to $1,100 per cubic yard for the base portion of the trench. The main factor impacting this range of costs is the system for securing racks or supports for the piping. This can be as simple as providing threaded inserts cast into the walls to accept bolts. Other methods could include providing a cast in support system such as Unistrut or providing cast in weld plates to allow for a welded connection of pipe supports. The materials can range from standard black steel to stainless steel, to non-metallic materials such as fiberglass. The length between the necessary pipe supports is generally dictated by the type of piping material used and how much support is necessary. We see support systems ranging anywhere from 5 ft to 20 ft between supports.

COST OF CONCRETE STORM WATER DRAINAGE TRENCH

There are fewer variables with trenches used solely for the purpose of water conveyance. The cost of concrete drainage trench can range between $750 to $1,100 per cubic yard of concrete.

Drainage trenches typically have a steel or iron grating system to allow for storm water runoff to enter the trench system. Again, the loading conditions and the width both play a big role in determining the ultimate cost of these grating systems. The range of costs for drainage trench grating systems is $100 to $800 per linear foot of the trench, which is very much dependent on the width of the trench.

COST OF DELIVERY FOR PRECAST STRUCTURES

So now you know how to get a close estimate of the cost of your precast structure…your next question is “How much extra will I have to pay to ship my precast concrete structure to my job site?” We are here to help answer that question as well and you can find information here about Best Practices for Shipping Precast Products.

Just like anything else being shipped, the cost for delivery is a function of weight and distance. Being able to utilize the full capacity of a flat-bed truck will reduce your cost per cubic yard of concrete. Typically, flat-bed trucks can hold about 46,000 lbs, so filling up the truck as close to this load capacity is ideal. The Department of Transportation rules do not allow you to add additional products to a truck if it starts to exceed its load limit. The rules allow shipping of a single structure that exceeds the load limit, but in that case, there are additional fees associated with permitting the load. These extra fees are incurred as a way of “taxing” heavier loads and providing more funding for roadway maintenance.

Assuming the structure is within normal shipping parameters, less than 9 ft wide and less than 46,000 lbs, you can expect to pay $575 to $850 per load if you are within a 100-mile radius. The cost increases the further away the job site is from the producing plant. Delivery cost ranges from $850 to $1,125 per load at 100 to 200 miles. As you get farther than 200 miles, costs can vary quite a bit depending on the trucking market. Interstate trucking brokers can potentially obtain backhaul rates that dramatically reduce shipping costs.

LESS THAN FULL TRUCKLOAD DELIVERIES

In the case your shipment is significantly less than a typically 18-wheel flat-bed load, there are smaller trucks and trailers available at a reduced rate. For instance, if you have a 7,000 lbs structure, your delivery cost would be around $450 to $700 per load within a 100-mile radius.

HOW BIG AND HEAVY CAN YOU GET?

A common question we hear is “How big and heavy can a precast concrete structure be and still be able to ship it?” Usually, people are surprised to hear we can ship structures over 200,000 lbs and over 100 ft long. Yes, the cost starts to increase dramatically as you get into these megastructures, but here is some guidance on what to expect.

OVER-WIDTH DELIVERIES

The standard shipping width not requiring a permit is 8 foot 6 inches or less. A structure that is over 8’-6” wide, but not more than 12 feet wide requires an over width permit ($550 to $825). Structures over 12 feet in width, but not more than 14 feet wide, require a permit and police escort ($800 to $1,400). Structures over 14 feet, but not more than 16 feet in width require a permit and two police escorts ($1,700 to $2,000) and shipments with product over 16 feet in width require permits, escorts, and close coordination with the Department of Transportation and can cost more than $2,200.

OVER-HEIGHT DELIVERIES

Similarly, to the width scenario, a truckload with a total height of 14 feet or less from the ground up is considered standard. Shipments (including the product and trailer height) taller than 14 feet are more complicated and it depends on the route from the producing plant to the jobsite to determine the cost. Typically, taller shipments must be re-routed to avoid bridges and could potentially require a bucket lift escort to raise overhead power and communication lines during the shipment. The cost of this is relative to what type of height obstructions are between point A and point B. Fortunately, most precast concrete structures can be designed and broken into shorter sections to avoid these situations.

OVER-WEIGHT DELIVERIES

We all know concrete is heavy…and strong. That is part of why it is such a great building material, but it can create challenges when shipping it. As mentioned above, the typical flat-bed truck has a load capacity of about 46,000 lbs depending on the truck. A single structure heavier than the load capacity will require an overweight permit. This overweight permit varies, but for a load between 46,000 lbs and 60,000 lbs, this permit cost can range between $300 to $350. As the weight continues to increase, the cost of permits will increase and potentially other costs will come into play as you consider other factors such as the route of the delivery, load capacity for bridge crossings, and weight per wheel on the trailer. As you start getting above 85,000 lbs for the load, specialty trailers with extra wheel axles are needed to handle the load. As you get above 175,000 lbs, even more specialized equipment is needed to handle the shipment and the extra costs can range from $5,000 to $20,000 per load depending on the length, width, and height.

These are guidelines meant to help in putting together cost estimates for your next precast concrete project. As you can see, there are quite a few variables that can impact the overall cost but working with your local precaster when designing your project, you can eliminate unnecessary costs and build in great features to reduce your onsite installation costs.

We hope this article was helpful. Please send in your questions to info@lockesolutions.com and we would be happy to help answer them.