How do you seal up precast concrete joints and what are the most common concrete joint sealants used?

Manholes, Catch Basins, Sumps, Culverts, and Trenches are just a few structures that often require joint sealants. To ensure that the joints are properly sealed, it is important that the correct steps are followed and that the right type of joint sealants are used.

Before precast concrete joints can be sealed, it is important to check that the joints are properly prepared for the application of the joint sealant. It is crucial to ensure that the joints are level and completely clean and free of any dirt or debris. At this point, a primer may be used to help create a more adhesive bond between the sealant and the concrete surface. Once the joints are inspected, the application of the joint sealant can begin.

“When sealing precast concrete joints, it is important that the joints are clean and completely straight. The sealant must also be applied properly to the joints. If this is done correctly, the structures will not leak, and this is the main goal with sealing precast concrete joints.”

-Andy Gemmill

BUTYL-RUBBER BASED SEALANT

Butyl-Rubber-based sealant is a popular precast concrete joint sealant as noted in ASTM C990 “Standard Specification for joints for Concrete Pipe, Manholes, and Precast Box Sections Using Preformed Flexible Joint Sealants.” It often comes in strips and has a sticky texture similar to the consistency of tar. Press-Seal, ConSeal, and Henry are companies that provide Butyl-Rubber-based preformed joint sealants meeting this ASTM C990 specification.

Installation for Butyl-Rubber Joint Sealants

The two most common questions by contractors using this type of joint sealant are:

- Where should the preformed sealant be placed on the joint?

- What is the correct method for connecting the joint sealant to create a continuous seal?

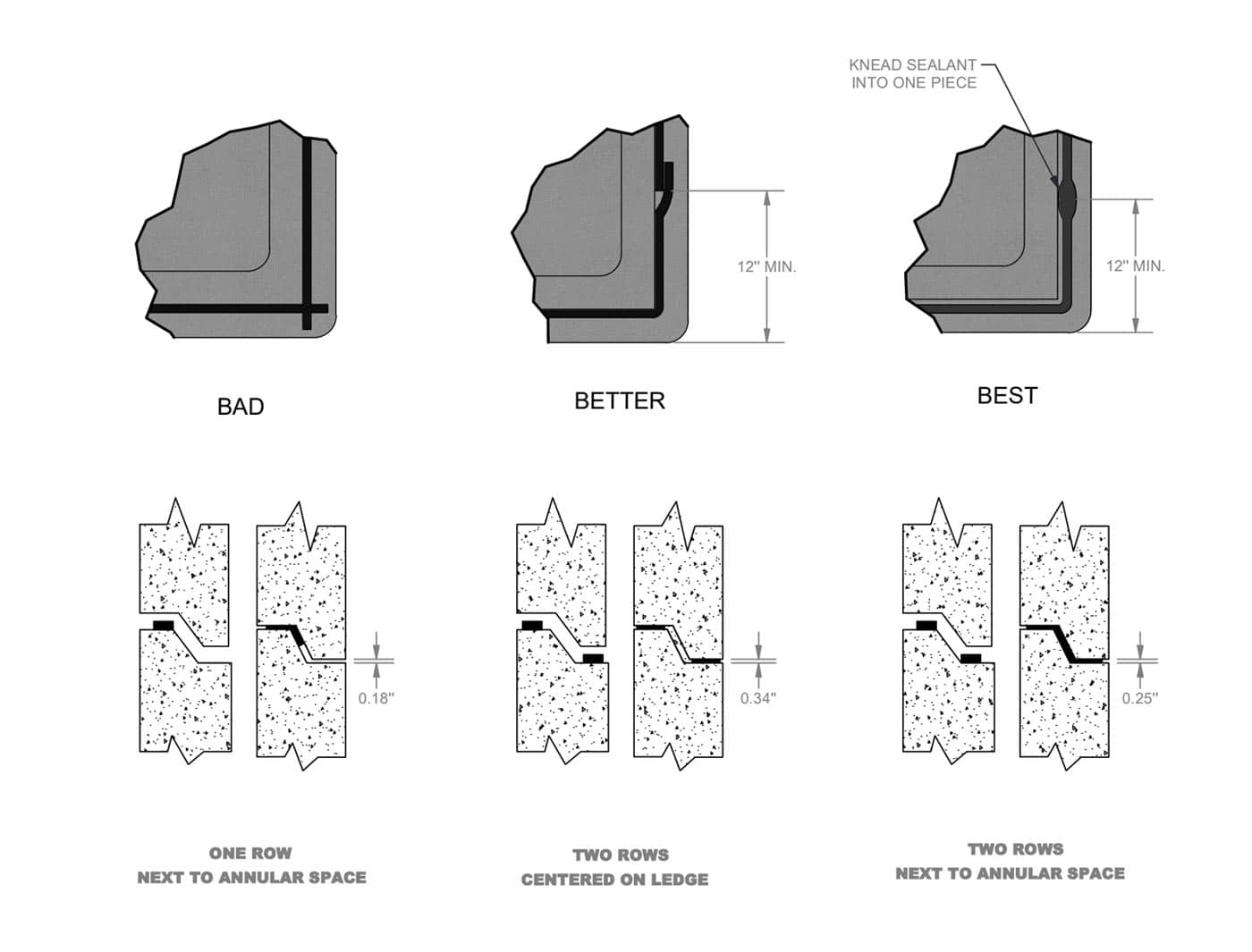

Location: The most common joint profile where butyl-rubber joint sealants are used is the single offset shiplap joint as shown below. As you can see, there are several acceptable positions for placement of the sealant, but a good rule of thumb for other joint profiles is to place the joint sealant as close to the center of the joint as possible.

Connection: These butyl-rubber-based preformed sealants typically come in pre-cut rolls or strips and when placing on the precast structure, it will require multiple pieces. To prevent a gap in the seal along the joint at this connection point, it is recommended to connect the two sections by kneading the ends together and creating a similar cross-section profile at the connection. It is also recommended to avoid connecting two pieces of sealant at the corner of a structure.

Installation of Sealant around a Corner

The outer wrapper on the sealant should be left on to keep it clean and prevent over-stretching while placing the sealant along the joint. Once the strips are in place, the wrapper may then be removed prior to placing the next precast section in place. After setting the precast sections together, the butyl-rubber sealant will compress, and it is normal for the sealant to slightly ooze out from between the joints. Depending on the ambient conditions, the rate of compression will vary, and it is recommended to wait about 10 minutes to allow the sealant material to reach maximum compression.

If the use of a primer is required before placement of the butyl-rubber sealant, several options are available including ConBlock SH, CS-50, and CS-75, all of these provided by ConSeal with different features.

- ConBlock SH – this primer is applied in advance and developed to absorb into the concrete and react with the calcium hydroxide turning it into a hardened crystal.

- CS-50 – a solvent-based liquid butyl primer applied in advance filling in the micropores of the concrete with rubber creating a great bond for butyl-rubber sealants.

- CS-75 – a water-based adhesive primer that leaves a tacky surface applied at the time of sealing.

Butyl-Rubber based Joint Sealants:

- CS-102 Butyl Rubber Sealant

- RN 101-Ram-Nek Preformed Flexible Plastic Gasket (Strips)

- EZ Stik Premium Butyl Sealant

HYDROPHILIC ELASTOMERIC JOINT SEALANT

Another type of joint sealant is a hydrophilic elastomeric joint sealant. Examples of this type of sealant include Sika’s SikaSwell and ConSeal’s CS-1900 providing a swellable waterstop to seal up precast joints and concrete construction joints. These sealants are provided in various forms and can be applied with caulking guns or placed as strips similar to the butyl-rubber preformed strips. The technology with these sealants provides a swelling effect of the sealant when it comes in contact with water creating a watertight seal in the connecting joints.

Hydrophilic Elastomeric Joint Sealants:

GROUT CONNECTION

Joints between precast concrete sections are sometimes connected using a cementitious grout. Grout is a mixture of water, sand, and cement that is mixed and can reach compressive strengths of 6,000 to 10,000 psi at 28 days of curing. Often cementitious grouts are used to bed the joints between precast sections or to facilitate a structural connection with projecting reinforcing steel embedded into a pipe sleeve. Whether creating a bed of grout or pumping the grout into open cavities between precast sections, the joint should be prepared to remove all dirt, oil, grease, and other loose material that could prevent a strong bond with the grout. The joints should then be carefully aligned, joined together, and any excess grout that squeezes out can be wiped away.

There are numerous manufacturers of cementitious grout, but below is a shortlist of common materials.

- SikaGrout-212 – General Purpose Cementitious Grout

- Quikrete Non-Shrink Precision Grout

- SpecPatch 30 – General Purpose Cementitious Grout

FUEL AND OIL RESISTANT JOINT SEALANT

Occasionally there is a need to provide joint sealants able to resist certain chemicals such as fuels and oils. When working on industrial sites or dealing with stormwater or sump systems with potential hydrocarbon contamination, it is critical to pick the right joint sealant that can hold up to the potential chemicals. Each situation is different, but here are a few joint sealant products that can be useful in these situations.

- Kent Seal Oil & Fuel Resistant Butyl Sealant

- CS-440 Fuel & Oil Resistant Sealant

- Sika Duoflex NS Polysulfide Sealant

Regardless of the chemicals you are encountering, more than likely there is a suitable joint sealant to handle the job.

Stay tuned for the next article!